Search for topics or resources

Enter your search below and hit enter or click the search icon.

Our previous blogs showed how to use orchestrations to export data from and import data into JD Edwards EnterpriseOne. But they can do much more than that. Orchestrations can also automate business processes, making them great for IoT integration.

IoT, IIoT, Industry 4.0—whatever you call it, these terms imply the use of a connected device to improve data communication. For manufacturing companies, it may be a smart device on the shop floor that transfers mission-critical information to production stations. For companies with fleet maintenance responsibilities, it could be one that collects and shares detailed insights about vehicle and driver operations. Generally speaking, IoT solutions involve an Internet connection, but not always an ERP system. That's where orchestrations can help.

Imagine this scenario: you have numerous industrial devices on your shop floor capturing operational data. Your goal is to combine top-down, planning information (stored in JDE) with execution level information (stored in MES) to create a connected manufacturing solution. Traditionally, transferring data between the various systems involves point-to-point interfaces. They are complicated to build and error-prone as updates are applied. Enter orchestration. Orchestrations can act as a gateway to JDE, where critical business processes and data are stored.

IoT integration patterns enable you to build an end-to-end solution in a well-specified way. Below are the three we use most to integrate IoT devices with JDE using orchestration.

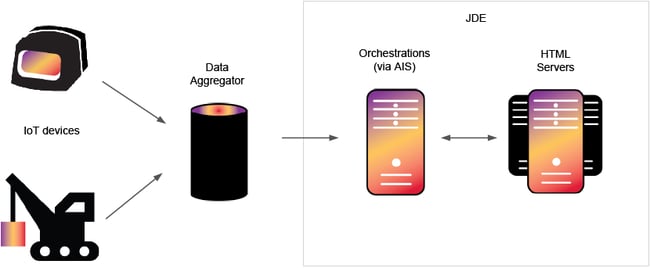

Shop floor machines hide a great deal of useful information. They also contain granular data not needed in JDE. In this pattern, an IoT device first pushes raw data to an intermediary application for aggregation. Only the valuable information then moves on to JDE.

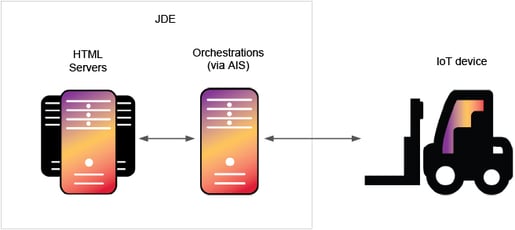

In our next pattern, an orchestration communicates directly with the IoT device. Often the orchestration is built to perform an action or query for information such as status. Automating the data exchange between JDE and the IoT device saves substantial time and lowers the risk of error.

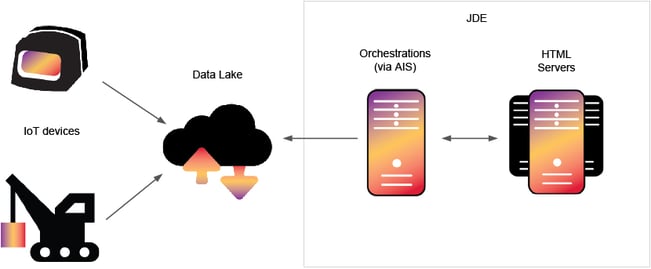

Our third pattern is beneficial when the end goal is unclear. Both the IoT device and JDE send data to a central location or data lake. Data lakes are an excellent option for storing both structured and unstructured data. Here, large amounts of disparate data can be analyzed for patterns and efficiencies.

IoT devices hold the information employees need to make optimal business decisions. Orchestration makes it available across your JDE footprint. And real-time, relevant data prompts a quicker response moreover, process efficiency. That's a pattern worth exploring.

Points to remember when getting started:Need help getting started? Click to learn about Orchestrator Services. ERP Suites is a JD Edwards Gold Partner and winner of the 2019 Oracle Distinguished Partner Award for Successful Adoption of Orchestrator.

As the Chief Advisory Officer at ERP Suites, Eric Poff sits on the leading edge of digital technology. Customers lean on him to drive meaningful process improvement with measurable results. His product development and work with Orchestrator have earned ERP Suites several JD Edwards Distinguished Partner Awards. He is also a frequent conference presenter dedicated to bringing digital transformation within reach.

Topics: