10 Barcode Flows For JDE Users To Increase Efficiency

November 20th, 2023

3 min read

In the world of warehouse management, the ability to seamlessly communicate, transfer, and control your business processes is essential. Imagine your warehouse as a symphony, each process as a distinct instrument, and the overall composition as the flow that ties it all together. This is precisely what flows are in the context of ERP Suites Scanability, a robust and integrated JD Edwards (JDE) barcode solution, and why they play a pivotal role in enhancing the efficiency of your operations.

Scanability Flow Essentials

First things first, what exactly is a flow in Scanability? In essence, a flow is a communication channel, a transfer, a user interface - think of it as a unique business process or a vital component of a process. Whether it's a transfer transaction or a picking operation, all these activities fall under the umbrella of flows. These flows are not limited to specific modules; they can encompass various aspects of your business, from inventory and location control to your sales order processes and beyond.

Standard Flows Within Scanability

Scanability offers an array of standard flows designed to streamline your warehouse operations – in addition to some proprietary flows that can be implemented on an a la carte basis. Let's explore some of the key standard flows that have proven their worth, time and client again:

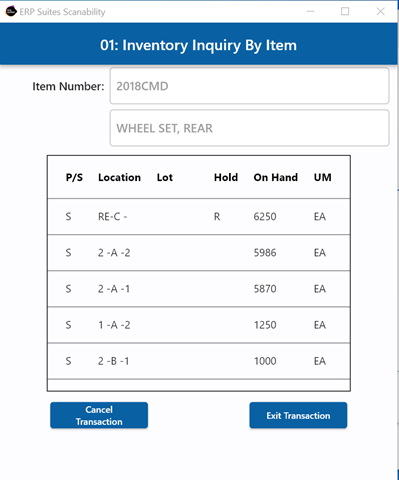

- Inventory Inquiry by Item

With a simple scan of an item number, you can access real-time information about on-hand inventory, the specific location, and the quantities available in those locations.

- Inventory Inquiry by Location

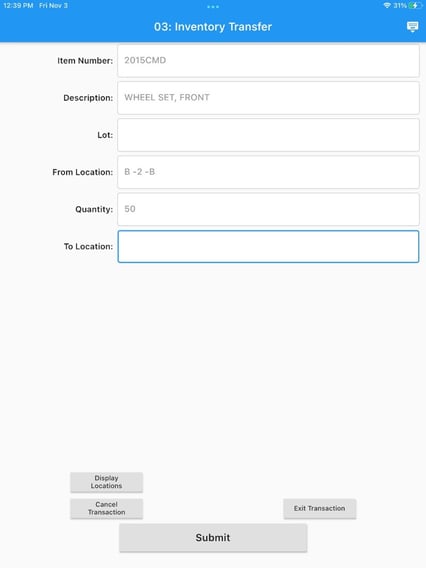

This flow allows a user to scan a location and see all of the available items and quantities, including those on hold or committed, in that specific location. - Inventory Transfer

Need to move items from one location to another? Scanability makes it easy. Scan the item, source location, and quantity, and watch the magic happen in real time.

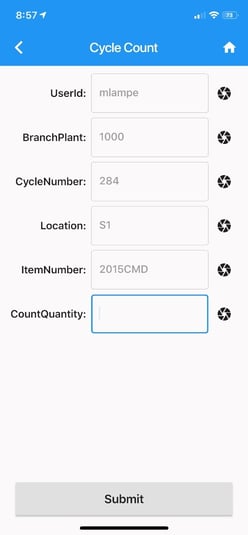

- Cycle Count

Streamline your cycle counting process. Instead of the traditional approach of manual counting, Scanability guides you through the process, optionally allowing simultaneous, directed inventory location counts by multiple associates, ensuring minimal discrepancies and taking transactional activities into account.

This last component is proprietary to Scanability – while other warehouse and manufacturing solutions can perform cycle counts, the real-time transactional nature of a business is only taken into account by our Scanability software. This cuts down on workload and makes the cycle count process even more efficient.

- Cycle Recount

Second looks need to be performed for confirmation. The cycle recount flow allows you to validate and correct counts swiftly. - PO Receipt

This flow simplifies the purchase order receipt process. It validates the item against the order and puts it into a virtual location – effectively a two-stage receiving process that ensures accuracy. - PO Putaway

Scanability takes a unique approach and stands out from the competition in the scanning market by optionally directing users to the location with the largest quantity of the product, simplifying the putaway process. No more will your warehouse manager need to confirm quantities with a piece of paper or on sight; Scanability’s PO Putaway flow eliminates the potential for manual error. - Work Order Completion

When completing work orders, Scanability can handle super backflushing, relieving inventory for all components on the parts list attached to the work order, rather than the more tedious manual issue of discrete quantities of each item. - Work Order Completion Putaway

This flow aids in efficient putaway operations after completing work orders. - SO Pick Confirm

Combining pick and pack confirmations, this flow simplifies the picking process and can even stage data for Advanced Ship Notices. This flow also allows a business to pick multiple orders or wave pick, allowing for larger quantities to be accounted for.

These standard flows provided as part of the ERP Suites Scanability library are widely adopted by businesses and are instrumental in improving warehouse efficiency.

The Personalization Factor

While the standard flows of Scanability are excellent for many businesses, the beauty of the system lies in its ability to be personalized. No two warehouses are identical, and Scanability recognizes this fact. It's about personalization to meet your specific needs.

Personalization may be necessary when dealing with unique requirements. For instance, Ford Meter Box, which handles valves, needed a specialized solution due to stringent regulations. They use an XRF scanner to check if valves have materials like brass or steel that are not permissible in the United States. This specialized requirement was met by Scanability, proving its adaptability. Standard orchestrations can quickly be turned into custom, configurable workflows, offering limitless ways to configure Scanability. In return, customers who migrate have seen a significant reduction in scripts to workflows.

License plating is another feature that Scanability brings to the table, which isn’t part of the standard JDE warehousing module. This feature simplifies tracking and transferring items on pallets, making it a highly valuable option for some businesses.

To adapt to these unique needs, Scanability collaborates closely with businesses, bringing JD Edwards expertise in each respective area of the warehouse and shop floor. This personalized approach ensures that your workflows are optimized to the fullest.

The Power of Consultation

When implementing Scanability, it's not just about the technology. It's about the wisdom and expertise that comes with it. ERP Suites serves as an advisor, helping businesses streamline their operations, adapt to best practices, and optimize their warehouse processes.

In conclusion, Scanability and its standard flows are a remarkable solution for businesses looking to enhance their warehouse management. These flows are a great fit for many, but they are also malleable and can be tailored to your unique requirements. Whether you are a part of the mainstream adoption of standard flows or have specific needs that necessitate personalization, Scanability is your partner in enhancing warehouse efficiency.

Leyla Shokoohe is an award-winning journalist with over a decade of experience, specializing in workplace and journalistic storytelling and marketing. As content manager at ERP Suites, she writes articles that help customers understand every step of their individual ERP journey.

Topics:

.png?width=650&height=325&name=Blog%20Images%202_1%20(4).png)

.png?width=650&height=325&name=Blog%20Images%202_1%20(5).png)

.png?width=650&height=325&name=Blog%20Images%202_1%20(3).png)

.png?width=650&height=325&name=Blog%20Images%202_1%20(2).png)

.png?width=650&height=325&name=Blog%20Images%202_1%20(1).png)

.png?width=960&height=540&name=Blog%20Images%20(96).png)

.png?width=960&height=540&name=Blog%20Images%20(90).png)

.png?width=960&height=540&name=Blog%20Images%20(88).png)

.png?width=960&height=540&name=Blog%20Images%20(87).png)

.png?width=960&height=540&name=Blog%20Images%20(86).png)

.png?width=960&height=540&name=Blog%20Images%20(85).png)

.png?width=960&height=540&name=Blog%20Images%20(83).png)